Drilling Waste Management

Slop Treatment.

Our specialist services offer the safest processes for the efficient planning, monitoring and treatment of slops.

By combining with our RotoMill solution, you can treat the entire range of drilling waste generated, further reducing your costs and carbon footprint.

Explore This Solution

Overview

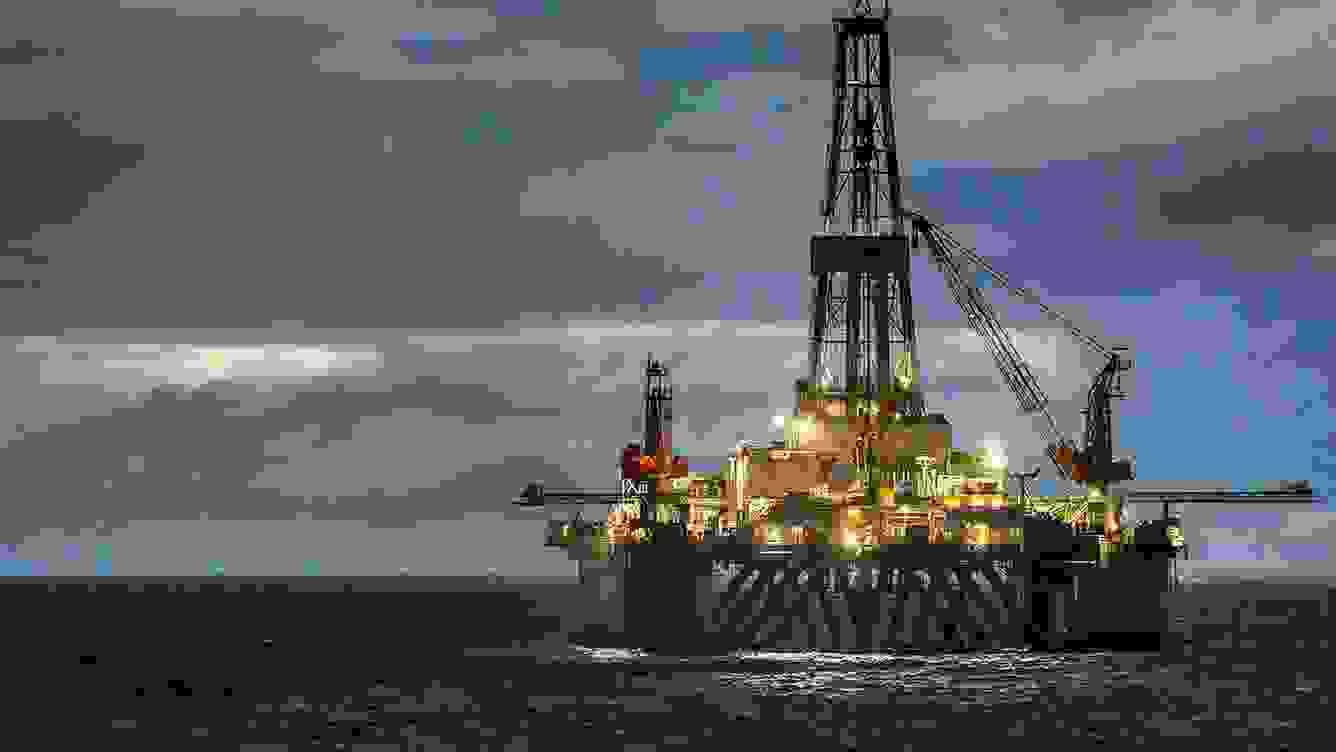

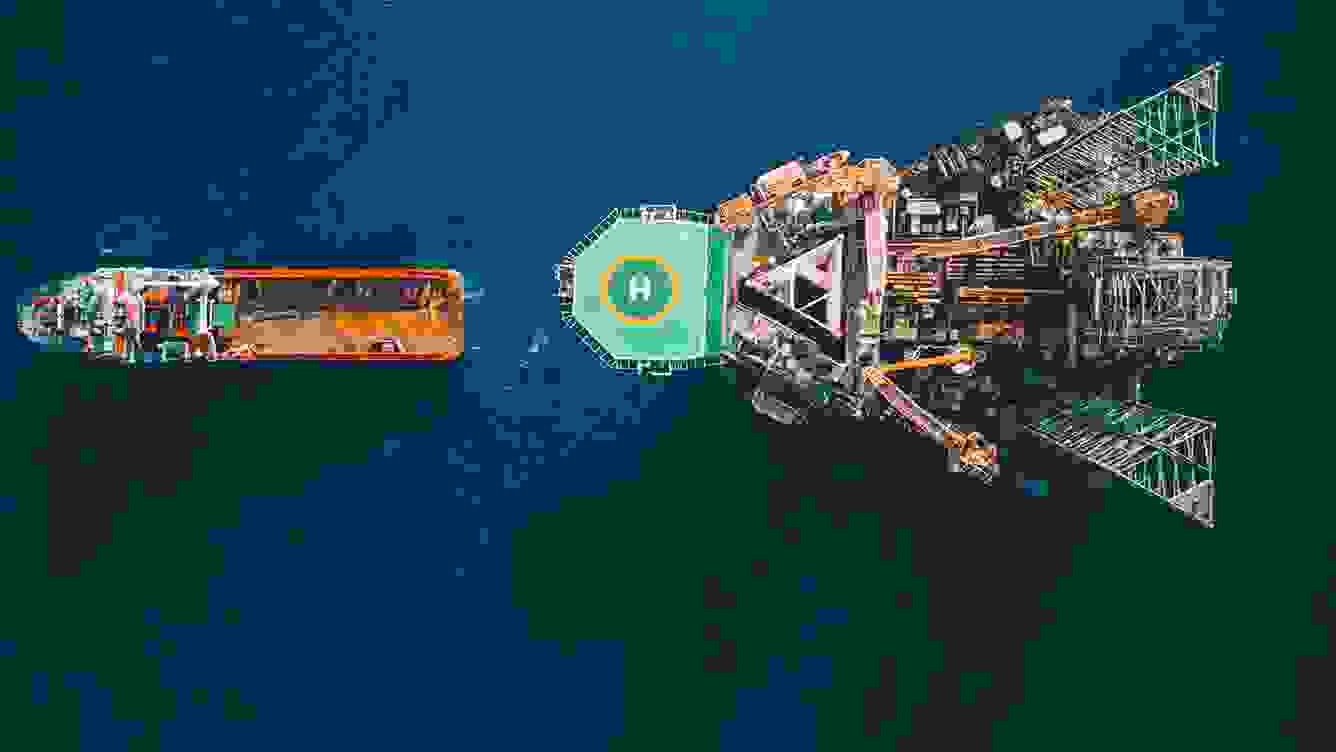

Versatile slop treatment solution at source to eliminate haul off from site.

Onshore and offshore treatment solution to manage a wide variety (lightly contaminated water to spent drilling fluid) of slop generated at source.

Two distinct product types, mechanical separation to treat heavy/weighted slops and dissolved air floatation (DAF) to manage slop with light, low gravity solids.

TWMA site-based slop treatment offers lower total cost of ownership to our clients by reducing haul off by up to 95%.

Solution that can be easily integrated into any location (onshore and offshore) and requires minimal man power to safely and efficiently operate.

Solution that has been proven to reduce and, in some cases, eliminate multiple levels of handling and transfer of a hazardous waste stream thus significantly improving the overall HSE impact of managing slop waste.

Operating Detail

Slop management plan designed to reduce waste generated at source and add value to your operation.

Our solution to slop does not end with the supply of equipment. A team of specialists will be assigned to create and execute a customised slop management plan for your project. An effective slop management plan considers operation, environmental, safety and financial factors.

The benefit of the TWMA slop management plan is that we firstly identify the source of slop, minimise it as much as responsibly possible. From there we can apply a single or dual stage treatment method at source, designed to recover value from the waste and reduce the total cost of ownership related to disposal.

The solution acts as a blueprint for future campaigns and a new best practise to minimizing waste at source.

FEATURES & BENEFITS

Multi stage process minimises chemical consumption.

Compact modular system, designed to be installed in all locations.

Minimal personnel requirements to manage system.

Eliminates the need for costly logistic and storage onshore

50% reduction in carbon emission through elimination of logistics

Reduces HSE exposure related to loss of containment by processing at source

Real-World Results

Quality engineering.

Proven performance.

-

Case Study

Case StudyPit & tank cleaning solution reduces slops by 60%.

TWMA trained specialists complete pit and tank cleaning to improve safety performance and efficiency.

Author -

Case Study

Case StudyTCC RotoMill® recovers base oil worth $24m.

TWMA recovers base oil worth $24m with world first at source drilling waste handling, containment and treatment solution.

Author -

Case Study

Case StudyTWMA saves AGR more than $500k with TCC RotoMill®

TWMA reduces total cost of ownership by 35% across a one well campaign.

Author -

Case Study

Case StudyTWMA reduces well cost by 35% on North Sea campaign.

TWMA delivers $1.2m in savings over a two well campaign representing a 35% cost saving compared to skip and ship.

Author

MAXIMISE EFFICIENCY AT THE WELLSITE.

We have the experience to deliver the value back on the economics of your operation.

Andrew SutherlandProduct Line Champion

Seeking Seamless Integration?

Our wellsite solutions return more value when they work together.

Need Solids Control Solutions?

Explore our solids control solutions for water and oil-based mud systems.

Looking For Products?

Browse our high-quality products and equipment that keep you turning.